3D Concrete Printing Market Insights by Growth, Emerging Trends and Forecast By 2027

Written by: Allied Market Research

Publish Date: December 01, 2020

The report analyzes the global 3D concrete printing market on the basis of printing type, technique, end-use sector, and region. The printing types covered in this report are gantry system and robotic arm. The techniques taken into consideration in the study include extrusion-based and powder-based. The end-use sector segment is segregated into residential, commercial and infrastructure.

Region wise, the market analysis is conducted across North America (the U.S., Canada, and Mexico), Europe (Germany, France, the UK, Denmark, and rest of Europe), Asia-Pacific (China, Japan, India, South Korea, and rest of Asia-Pacific), and LAMEA (Latin America, the Middle East, and Africa).

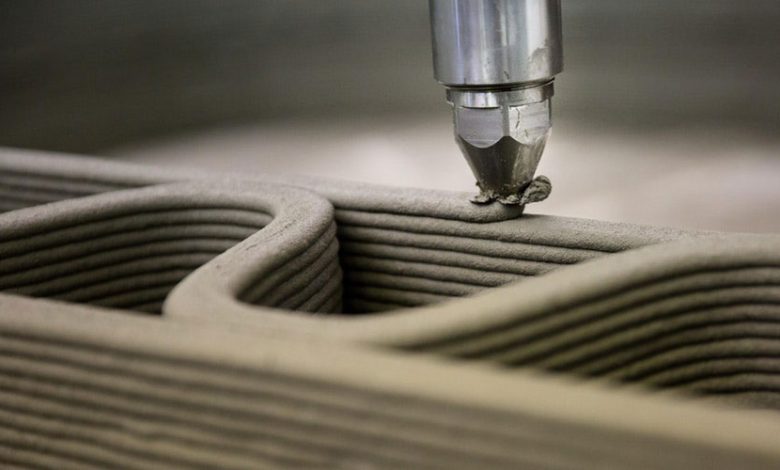

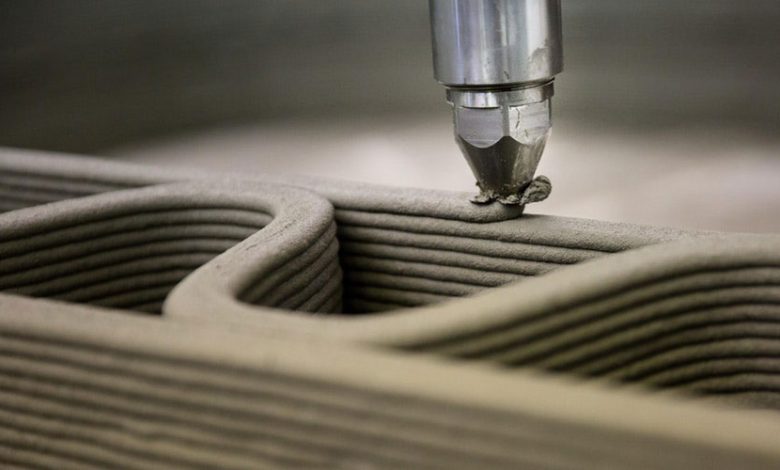

Global 3D concrete printing market size accounted for $310.9 million in 2019, and is expected to reach $40,652.4 million by 2027, registering a CAGR of 106.5% from 2020 to 2027. In 2019, North America dominated the global 3D concrete printing market, accounting for around 42.1% share of the global 3D concrete printing industry, followed by Europe.3D concrete printing refers to construction of building structures and other aesthetic structures in various sizes and shapes by using automated printer. The printers are operated through feeding the program in the software. This software will operate the printer to travel in the desired path that is been programmed into it. The dispensing of concrete through the nozzle is also controlled by the software. Extrusion-based 3D printing uses a screw device or pneumatic actuator to feed material through a cartridge and into a needle or nozzle for layer by layer deposition. Conversely, powder-based 3D printing is the process carried out by depositing binding solution onto the ceramic powder bed through a print nozzle. This leads to bonding of these surface areas together to form the pre designed solid part laying one layer at a time. Upon drying the concrete, the product is extracted from the bed and excess powder is eliminated by air jet sprays. Ready-mix, high-density, precast, and shotcrete are the material types that are commonly used for 3D printing. However, these material types are produced with various grades of materials depending on their application.

High cost of skilled labor increases the overall cost of the project. Moreover, complicated designs incur extra cost as well as consume excess time, if built manually. Despite of this, one cannot guarantee flawless and desired output due to manual errors. With the use of 3D printers, exact output and minimum wastage of construction material could be achieved. Moreover, mass production of irregular or customized shapes and sizes can be affordable and time saving.

However, high capital cost of the printers and their operating systems act as major the restraint of the market. Moreover, the outbreak of COVID-19 pandemic has negatively impacted the market. To prevent the spread of the virus, governments across various countries have implemented lockdown. Thus, construction and production activities were partially or completely closed due to the lockdown. This affected the 3D concrete printing industry as well as led to the disruption of the supply chain. However, reopening of production facilities gradually is anticipated to re-initiate the production of concrete and 3D printer companies at their full-scale capacities.

About the Author

This article is written by Allied Market Research

Read the original post here.